Features and Capabilities

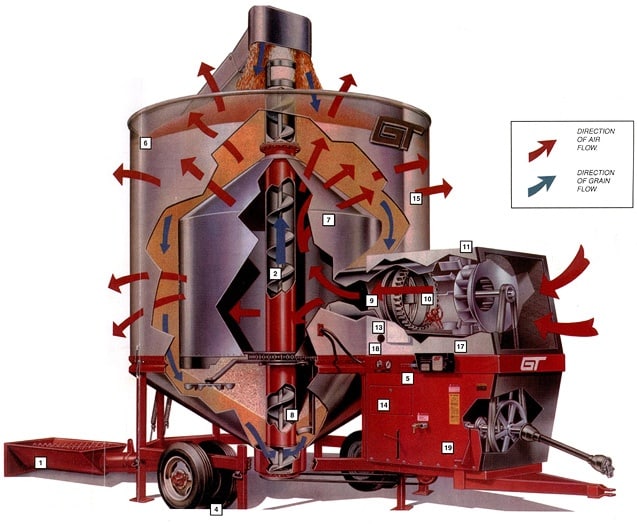

Understand The Flow of Your GT Dryer

Completely Self-Contained All you need for high-speed high-quality drying is a GT RB Dryer, a tractor and propane. Average set-up time is 30 minutes.

1. Loading Hopper eliminates the need for separate augers. Load directly from your truck or grain wagon.

2. One 12″ auger recirculates and unloads grain gently. Low 275 RPM operation keeps grain column full for controlled, even drying. Seamless tube and spin-balanced auger with heavy-duty fighting reduce wear and mechanical fatigue.

New Superflite” High Durability Flighting

Super Edge” flighting provides up to 50% extra thickness at the exact location where the greatest wear occurs. Designed specifically to combat auger wear, the added strength is achieved with no increase in weight. Super Edge” Flighting features a brand new design, thanks to a patented, cold rolled steel process. Patent No. US5678440

3. Built-in grain sampler collects grain for moisture testing from the center of the grain column.

4. Completely portable for easy transport anywhere – work, yard or field. Tires and hitch are standard. The top section of center auger removes easily. Loading hopper folds up for out-of-the-way storage or transport.

5. Centrally located controls provide complete control of the drying process from one location. Additional gauges or monitors are not needed.

Uniform Drydown

6. Round bin design evenly distributes heated air for uniform drying of any crop. Hot and cold air pockets are eliminated. Grain flows smoothly since it dries without bridging.

7. Perforated (3/32″) inner chamber distributes heated air evenly through grain column. Heavy-duty formed skirts provide greater durability.

8. Positive agitator arms keep grain moving downward into the central auger at a slow, gentle rate of 8 RPM. The grain is in constant motion during the entire drying process. Convex rollers guide agitator arms for trouble-free operation.

All-Weather Drying

9. Built-in vaporizer allows accurate, fuel-efficient drydown, even in sub-freezing temperatures. GT’s vaporizer “pulls” liquid propane from the bottom of the tank and converts it to vapor.

10. Efficient stainless steel, ring burner assembly is designed to keep drying costs to a minimum. Delivers evenly heated air to the drying chamber at constant temperatures.

11. NEW In-Line Centrifugal fan delivers powerful airflow while reducing noise levels by 27 decibels. The workplace is safer, healthier and more comfortable. (Fan guard removed for photographic purposes. Always operate the dryer with all safety guards in place.)

Quality Built, Simple to Service

12. Service access door slides up and out for monitoring of the agitator drive.

13. & 14. Modular access panels on the power frame offer quick access to plumbing and electrical controls.

15. Space-age coating ensures a great, long-lasting appearance with minimum upkeep.

16. NEW central lube location makes lubrication maintenance a breeze. One central location provides access to all lubrication points except the tumbler shafts.

Micro-Pro Controls for Safe, accurate Drydown

17. Complete drying control is assured. Once the dryer is set for a specific maximum grain temperature, the dryer automatically shuts off when the set temperature is reached-load after load even when beginning moisture content varies with each load.

18. Safety controls with digital indicator automatically monitor all drying functions: drying temperature, grain temperature, flame failure power failure, fan failure, fuel supply, agitator, auger, PTO. If any of these functions fail, the gas supply automatically shuts off.

18. Safety controls with digital indicator automatically monitor all drying functions: drying temperature, grain temperature, flame failure power failure, fan failure, fuel supply, agitator, auger, PTO. If any of these functions fail, the gas supply automatically shuts off.